Research Paper on Ravi Raju's Water Fuel cell

Replication

Stanley Allen Meyer

Panacea-BOCAF On-Line University Research Paper on Ravi's

Water Fuel Cell Voltrolysis Replication

Panacea-BOCAF On-Line University

"Breakthrough In HHO Production"

I'm not here to argue whether things work as per

the preset laws of physics or thermodynamics but you need to keep an

open mind to evolve and see if something actually works. I'm an

engineer and been taught that things don't work if you break the

laws. Well I know my laws thank you. I've been making cells for the

last 8 years but now I've got something that works. If people want

to replicate it they can I'm giving out info on how to do it if they

don't want to fine by me! I'm getting nothing nor losing any thing

by this. Stan wanted to sell his units! well I'm not! This is for

the people who are already trying it out and who want to do

something about the environmental mess the world is in, its

accelerating by the year and it wouldn't be long before that the

powers be would realize that most of these changes are irreversible.

Vanishing Glaciers, melting polar caps, Europe has seen the hottest

summers in living memory and now Asia is going through the worst

floods in the living memory. We are heading for a disaster and have

already reached a point of no return with the fossil fuel addiction.

Its time we make ourselves count by Creating this togeter now! The

Internet is really accelerating this success beyond anyones ability

to stop it. The Internet is really accelerating this success beyond

anyones ability to stop it. You can do this. Please learn all you can

|

|

316L Stainless Cavitation Info

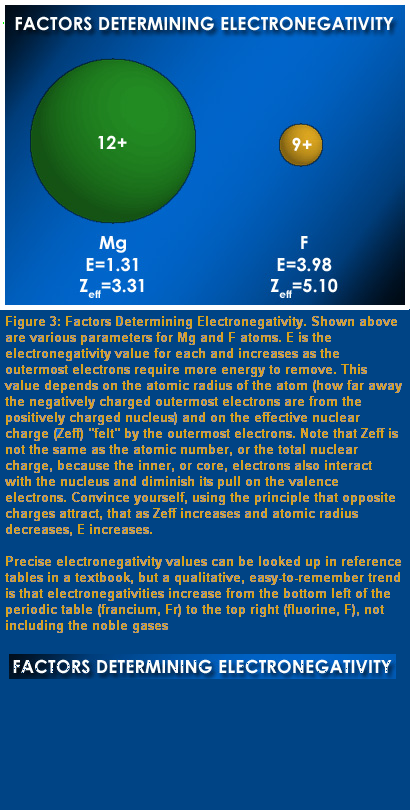

Surface modification of AISI 316 stainless steel using various forms of NiTi for enhancing cavitation erosion resistance. In this study, NiTi powder was preplaced on the AISI 316L substrate and melted with a high-power CW Nd:YAG laser. With appropriate laser processing parameters, an alloyed layer of a few hundred micrometers thick was formed and fusion bonded to the substrate without the formation of a brittle interface. EDS analysis showed that the layer contained Fe as the major constituent element while the XRD patterns of the surface showed an austenitic structure, similar to that of 316 stainless steel. The cavitation erosion resistance of the modified layer (316-NiTi-Laser) could reach about 29 times that of AISI 316L stainless steel. The improvement could be attributed to a much higher surface hardness and elasticity as revealed by instrumented nanoindentation tests. Among various types of samples, the cavitation erosion resistance was ranked in descending order as: NiTi plate > 316-NiTi-Laser> 316-NiTi-TIG >AISI 316L, where 316-NiTi-TIG stands for samples surfaced with the tungsten inert gas (TIG) process using NiTi wire. Though the laser-surfaced samples and the TIG-surfaced samples had similar indentation properties, the former exhibited a higher erosion resistance mainly because of a more homogeneous alloyed layer with much less defects. In both the laser-surfaced and TIG-surfaced samples, the superelastic behavior typical of austenitic NiTi was only partially retained and the superior cavitation erosion resistance was thus still not fully attained.

electrostatic excitation of covalent bond energetics causes the destructive catastrophic dissociation to occur! |

[Stanley Allen Meyer Page 3] Helping others to

make this technology feasible and easy to replicate whatever small

contribution no matter how much ever small to improve the air we

breathe would go a long way for our children's future.

We need people to know this side of science before

it's too late. Look at the change in the environment in the

last 100 years in the garb of development were ruining the

world we live in for the future generations and we are shown

a picture of development as prosperity actual fact being more

the prosperity more we ruin the environment for our creature

comforts its a vicious cycle we could introduce the alternate

science atplaces where its hurting the environment the most

at least in a small way. End quote- Ravi Overview Replication

Faculty information Panacea Endorsed Supplier of cells and

components Supplies Related Links Related Ravi Technical discussion

Videos & Credits Overview

The following research

paper is the first document in a sequence of material which will be

used to create a complete course on pulsed DC resonant systems. This

course will be coming to the Panacea University site soon. This

research paper mean time intends only to out line the specific

replication criterion which is necessary to duplicate Ravi's

water fuel cell results. All related faculty information,

validation data and further details of the water fracture process

will be included in the complete course material expected to be

ready in late 2008. Ravi Raju is a registered open source engineer

with Panacea and has recently disclosed his WFC replication success.

Ravi's version is based on the old (now upgraded) Panacea university

"D14" plans. These plans originated from the disclosures and device

of open source engineer Dave Lawton.

Stanley Allen Meyer Page 3 Dave Lawton's success in

constructing a working VERSION of the Meyer WFC was

reported to produce gas at 3x the Faradic equivalent rate for the

power consumed. Dave, who spent much of his career at Britain's

Rutherford Labs (equiv. U.S. Lawrence Livermore) designing and

constructing instrumentation for high energy particle physics

research, is far from the average 'tinkerer'. Videos of his two WFC

units, one with an

employing

solid state

timing logic, was posted on YouTube and has since received over

50,000 hits. The cells operated at 12-13v/3-4a - averaging

approximately 57 watts of input power - producing gas aggressively

in distilled water with no added electrolyte. The difference between

Ravi's replication results and Dave's is that Ravi built a

bigger cell and conducted a gas flow meter test. This gas flow meter

test proved with out any doubt that he had some thing closely

related to Meyer's original process. Meyer's results reportedly

showed an out put which was up to 1700% above Faradays law of

electrolysis. Thus it is only logical to

assume that the pulsed DC resonant systems are not conventional

electrolysis. Nothing about

this process involved in the Water Fuel Cell resembles electrolysis.

There is no electrolyte used; there is NO current admitted to the

water, in a proper system. No heating occurs in the water as it

produces gas. The gas produced is Hydroxy (aka HHO or "Brown's

Gas"), not differentiated Hydrogen and Oxygen; and all of the work

is performed by resonance and the voltage potential. As a result of

Ravi disclosing his gas flow test on Youtube.Com, intimidation

intended to interfere with his research resulted. Ravi was un lawfully

threatened. Continuing...

Stanley Allen Meyer Page 4 This

prompted public

action by the non profit organization and a reporting of this

incident to the authorities by us. Currently our subscribers keep a

public watch on Ravi's and the organizations actions. The public are

needed to assist in this task to stop energy suppression, please

subscribe to our news letter.

Only consolidated in this task can we effectively prevent engineers

from being harassed and enable them to freely present free energy

research to the public. The Non profit organization Panacea-BOCAF

intends to support open source engineers working with the WFC and

other suppressed clean energy technologies. These engineers require

grants, resources, faculty recognition and security. All this can be

created! For those able to help this effort, please contactPanacea's proposed granted research and

development center. Contact

us. Ravi's version of "D14" used bigger 9" (inch) tubes

and a 9 tube set. This gave him a resulting lower input current of

0.51 Amps from the frequency generator. Given the efficiency reports

by Ravi this technology is an invaluable power management process

which the mainstream faculties must benefit from. As an emission

cutting device andpower savings device alone, this technology

justifies (and needs) law for its

mandatoryimplementation. The Non profit organization

Panacea-BOCAF intends to support open source engineers working with

the Meyers other suppressed clean energy technologies. These

engineers require grants, resources, faculty recognition and

security. All this can be created in Panacea's

proposed granted research and development center. For those able to help this effort,

please Contact us.

Panacea's

Stanley Allen Meyer Page on Meyer's technology Description

Until further OPEN

SOURCE testing can be done, so far it is understood that there is

compound resonance present in the WFC (actually it is more of an

electrolyzer than a fuel cell). This compound resonance has so far

been evident in experimenter's cells. There is an electrical

resonance between the inductors (Resonant Charging Choke coils),

there is an electrical resonance within the electrode gap itself

within the water,and, finally, there is an acoustical resonance

between the cylindrical electrodes, which is somehow phase coupled

to the electrical resonances.The electrical resonance involves a

phase delay between the pulses to the electrodes, which has the

effect of inhibiting current flow into the cell; the acoustic

resonance may be producing a standing wave which inhibits ion

transport. Both of these contribute to dielectric breakdown in the

water, which is where electrons are ripped from the

water

(by voltage alone) and

as a result producing monatomic (browns gas) hydrogen in the

process. This concept and technology first surfaced in the 1990's,

individuals such Dr. Henry Puharich showed that by molecular

resonance the production of this gas are possible, as did Dr Yull

Brown hence the name Brown's gas. The reality of the hydrogen on

demand process became self evident with the emergence of the Stanley

Meyer's water fuel cell patent, which showed that conventional

electrolysis theory is incomplete and not the whole picture as

Stanley Meyer was able to create enough hydrogen out of the water to

run a car from as little as 13 volts and very little amperage.

Stan's efficiency's were calculated to be up to 1700%. Today this

pulsed resonant DC hydrogen on demand process is still currently

unknownand thought to be impossible by the mainstream

faculties. What mainstream faculties must realize is

that there is not one part of Water Fuel Cell operation which

resembles conventional electrolysis. Therefore the out

puts are not expected to resemble faraday's equations in any way.

(There is no electrolye; 2) There is NO current admitted to the

water, in a proper system; 3) No heating occurs in the water as it

produces gas; 4) The gas produced is Hydroxy (aka HHO or "Brown's

Gas"), not differentiated Hydrogen & Oxygen; and 5) All of the

work is performed by voltage potential alone. If you think how an

opera singer is able to split a 'memorex' glass with her voice, by

the pitch, volume, and frequency of sound waves, this is

aresonance with the glass and either splits, fractures or

cracks the glass. The simple way to explain what Stan Meyer is able

to do is he was using no current (ElectroStatic Voltage DC Feilds

plus DC Pulses added... 600cps 50% duty cycle with 42.8khz pulses

each half cycle) voltage @ resonant frequency.... instead of sound

to split the water from resonance created in the water by circuitry

and steel cylinders. It is understood that Stan harnessed the

voltage potential. There is still a lot of mainstream science doesn't

not yet have this in their curricula regarding voltage or electricity.

For example Tesla's Longitudinal and transverse

waves. Technically it is thought the gas results from an

electromagnetic deformation of the ionized water molecule to Hydroxy

(HHO), in which the Hydrogen atoms are bound magnetically, at less

than the 105 degrees separation classically attributed to H2O. This

results in a stronger magnetic polarization of the molecule, whereby

it also carries an additional electrical charge, and is recovered

upon combustion. The complete preciseness of the physical mechanism

involved is still not completely agreed upon today, however the

technology works. You can see this in certain industrial welding

equipment that use the unique properties of Brown's Gas. This has

been commercially available for over 25 years, removing all doubt as

to its existence. When the water fuel cell technology emerged In the

'90s, it was assumed by the energy suppressors, one would suppose,

that by murdering Yull Brown that Brown's Gas would [Stanley Allen Meyer Page 6]

disappear as a technical concept; or that with killing Stan Meyer

and Puharich, the WFC would 'dry up and blow away' They certainly

believed that if all THREE! Were out of the picture; the water fuel

issue would sink beneath the waves. There is no regulation at the

federal level committing grants and security into harboring the

manufacture of this suppressed alternative energy technology. The

current mandated laws do not prevent a corporate cartel based

influence from making or creating difficult economical or political

conditions to suppress this environmentally sound technology and

further harbor their own profit motives. They can also simply buy

the patent off the inventor and shelve it, there is no law

preventing them form this. Despite there currently being no

regulation and or social reforms into these matters, and these

murders the water fuel cell issue is very much alive and being

preserved today more then ever, this has only been able to be done

with the aid of open sources engineers, whom are part of a non

profit organization called Panacea-BOCAF. These engineers have

independently successfully replicated a version of the Meyers water

fuel cell from his patent and disclosed their results and

instructions open sourced on the organizations on Line University.

Why open sourced? Well, one can judge by history why this is the

only way. Examples can be seen in water fuel cell technology done by

an individual named Steve Ryan's who operates the Bios fuel

corporation, Steve presented a water powered motorcycle. In late

2005, there was a segment aired on the show "60 Minutes" in New

Zealand. This process may have used some sort of catalytic process

to turn the water into a usable fuel. When the non profit

organization recently asked Steve what happened to his technology,

he replied and I quote due to the current economic and political

conditions we are unable to bring you the water fuel cell technology

at this time. He now only sells a 50/50 mix of water and fuel.

Energy suppression does exist today, Stanley Meyer is thought to

have died of unknown food poisoning, other engineers with technology

have been removed also. Also recently the Xogen and black light

power cooperation both had working water fuel cell technologies,

plus 4 other companies have hydrogen on demand technologies,

including a very interesting effect patented by Prof. Kanarev, all

have not been able to publicly disseminate their technology. So

where does that leave the public, open sourced public disclosures:

Allow NO WAITING FOR SOME COMPANY TO GET A PATENT NO WAITING FOR

SOME MANUFACTURER TO GET PRODUCT OUT TO THE MASSES? NO SPECIAL

"HIDDEN COSTS" TO APPLY THE TECHNOLOGY! NO, "I CAN'T SHOW YOU

EVERYTHING BECAUSE OF INVESTORS" EXCUSES on the Electrostatic

Catastrophic Dissociation of HHO WFC VIC

[Stanley Allen Meyer Page 7] NO WAY FOR

THIS TO BE HELD BACK FROM THE PUBLIC IN ANY WAY EXCEPT FOR

GETTING THE WORD OUT! NUMEROUS PROVEN REPLICATIONS AROUND THE

GLOBE!!!!! This replicated version of the Meyer's technology

can be done on-board motor vehicles with a small auxiliary

device powered by the vehicle's electrical system, in effect

allowing the use of water as fuel to act as a boost to the

internal combustion engine and improve MPG significantly. The

combustible gas mixture produced is generated as needed, and

not stored aboard the vehicle, making it possible to burn

ordinary water in any Internal Combustion Engine, Turbine,

Furnace, or Torch, processing it into fuel on- demand, in

real-time, without transportation or storage of compressed or

liquid Hydrogen, caustic alkalis, catalytic salts, or metal

hydrides. This process yields only water vapor as exhaust,

which may be easily recovered by means of a radiator/heat

exchanger, and re circulated in the engine system if desired.

This is available for any one to replicate now on our on line

university. The organization has hundreds of registered

engineers who are seeking grants; a host of other water fuel

cell engineers have begun to join a distributed research

initiative to deliver practical, public domain technologies to

the world in an Open Source environment. All are prepared to

collaborate in a resource grant based environment, as can be

by done in the non profit organizations proposed granted

research and development center, where a whole host of

other technologies can be produced, all of which are profiled

on the web site. Meyer's original performance levels were

reported to be has high as 1700% efficiency from creating

molecular resonant frequencies in water. Currently this water

fuel cell technology needs further investigation to reach that

level, and has allot of potential. Recently tests on the

replication of the Meyer's WTF cell also showed effects of

cold current electricity. What is cold current electricity; it

was used by E V GRAY

in his patented radiant energy motors, where he was able

to light up light bulb underwater using cold current

electricity.

[Stanley Allen Meyer Page 7] NO WAY FOR

THIS TO BE HELD BACK FROM THE PUBLIC IN ANY WAY EXCEPT FOR

GETTING THE WORD OUT! NUMEROUS PROVEN REPLICATIONS AROUND THE

GLOBE!!!!! This replicated version of the Meyer's technology

can be done on-board motor vehicles with a small auxiliary

device powered by the vehicle's electrical system, in effect

allowing the use of water as fuel to act as a boost to the

internal combustion engine and improve MPG significantly. The

combustible gas mixture produced is generated as needed, and

not stored aboard the vehicle, making it possible to burn

ordinary water in any Internal Combustion Engine, Turbine,

Furnace, or Torch, processing it into fuel on- demand, in

real-time, without transportation or storage of compressed or

liquid Hydrogen, caustic alkalis, catalytic salts, or metal

hydrides. This process yields only water vapor as exhaust,

which may be easily recovered by means of a radiator/heat

exchanger, and re circulated in the engine system if desired.

This is available for any one to replicate now on our on line

university. The organization has hundreds of registered

engineers who are seeking grants; a host of other water fuel

cell engineers have begun to join a distributed research

initiative to deliver practical, public domain technologies to

the world in an Open Source environment. All are prepared to

collaborate in a resource grant based environment, as can be

by done in the non profit organizations proposed granted

research and development center, where a whole host of

other technologies can be produced, all of which are profiled

on the web site. Meyer's original performance levels were

reported to be has high as 1700% efficiency from creating

molecular resonant frequencies in water. Currently this water

fuel cell technology needs further investigation to reach that

level, and has allot of potential. Recently tests on the

replication of the Meyer's WTF cell also showed effects of

cold current electricity. What is cold current electricity; it

was used by E V GRAY

in his patented radiant energy motors, where he was able

to light up light bulb underwater using cold current

electricity.

[Stanley Allen Meyer Page 8] Dave Lawton's

cold current electricity demo, all photos courtesy of

Dave (Thanks Dave!) E V GRAY, like

Meyers was also killed. We at panacea feel that the

granted research and development center is needed to

create social reform, as the public will know why its

there and what subject matter goes on there, the main

stream faculties can also benefit from the organizations

findings and research and development., but we need

grants to survive. In the Mean time, any experimenters

can replicate the open sourced findings of this and

other technologies which are made available on the

panacea online university. Replication

| Element |

Percentage

by Weight

Maximum Unless Range is Specified |

| |

304 |

304L |

304H |

| Carbon |

0.08 |

0.030 |

0.04-0.10 |

| Manganese |

2.00 |

2.00 |

2.00 |

| Phosphorus |

0.045 |

0.045 |

0.045 |

| Sulfur |

0.030 |

0.030 |

0.030 |

| Silicon |

0.75 |

0.75 |

0.75 |

| Chromium |

18.00

20.00 |

18.00

20.00 |

18.00

20.00 |

| Nickel |

8.0

10.50 |

8.0

12.00 |

8.0

10.5 |

| Nitrogen |

0.10 |

0.10 |

0.10 |

Data are typical and should not

be construed as maximum or minimum values for

specification or for final design. Data on any

particular piece of material may vary from those

shown herein.

[Stanley Allen Meyer Page 9] To

achieve Ravi's efficiency, a strict selection and

preparation of stainless steel tubing is

important. The following parameters need to be

considered. (1) Choice of the grade of stainless

steel (2) Tube gap and Thickness / SWG / AWG of

tubes (3) Pre preparation and conditioning

[This sanding is typically done by hand or on a belt

sander using 60 or 80 grit sandpaper.]

Choice of the grade of stainless steel Stan

said he used T304 in line 52 of patent #

4936961. Ravi's choice was to use 316L seamless

pipes. Use ONLY SEAMLESS PIPES and not seam

welded. These tubes were annealed for 3 hours in

inert atmosphere of Argon to remove all residual

magnetism and cold work stresses before they were

assembled. Even Nitrogen can be used as the inert

atmosphere.

The tubes are annealed to get rid of the crystal

lattice imperfections induced due to cold work and

any traces of residual magnetism. They have to be

in bright finish only you don't want oxides of

nickel chromium or iron on the surface (more

details in preparation below). You can use most of

the 300 series Nickel-Chromium Steels but 316L

would be the most preferable and next would be

304L. Never go for 310 as this has the highest

resistivity among the 300 series. Avoid Inconel

grade (High Nickel Alloys) pipes as well due to

their high coefficient of resistance. Just between

316 and 316L there's a lot of difference in

resistivity of the material due to carbon

presence. Seam welds have magnetized seam lines

along the length of the tubes. You must have them

annealed after machining/cutting/sanding before

being assembled. If considering 316L stainless,

the slight increase in Molybdenum, Nickel and

Chromium would increase the Electric Specific

Resistance of the material ever so slightly, but

the thicknesses can offset this problem. One needs

to find out if there is any Aluminium content in

the grade. If the aluminum content is less than

0.5 Wt% or nil, you could use this if it is easily

available in seamless form and your required size.

The reason why you need to check for Aluminum

content is that it is used as a deoxidizer during

the melting and alloying process. So there is a

possibility of it remaining in trace amounts based

on the amount of O2 available in the bath for it

to turn to Alumina and float up in the slag.

Aluminum is the main component in Fe-Cr-Al alloys

which increases the electrical specific

resistance. Incase these manufacturers use Cerium

mischmetal or some other Rare Earths for

deoxidizing, we don't even need to consider Al.

The 316L seamless tubes Ravi used were sourced

from a retailer of Sandvik, Sweden'. Using

304

Stan

claimed he was using T-304 SS. As there is no

caustic electrolyte as such, is right to say that

304 grade s/s can be used. However, expect there

to be a good deal of brown gunk generated during

the conditioning process, with the additional part

coming from the 304 material. There are some

higher percentages of Ni and Cr in 316 and 2% of

Molybdenum. Some of the manufacturers use Cerium

Mischmetal (Rare earths) during the melting and

pouring operations and this is done in the more

expensive alloys like 316 to increase the hot life

and the surface layer strength and in case of

seamless tubes a little extra silicon is added for

free flow in hot condition (Hot Extrusion of

seamless tubes). All these put together add up to

different metallurgical properties of the material

in our case. When in hot condition the Rare

Earths, Silicon, Molybdenum tends to migrate

owards the surfaces of the metal and this helps in

the formation of a strong protective surface layer

(The reason why I said annealing was important).

SS 316L is the only SS that can be used in human

Medical Implants other than titanium, that's how

stable 316L grade is. In summary

-The best grade of SS to use is 316L. Next

preference is 316,304L and 304. L stands for Low

Carbon in the SS alloy. 316L composition: % Carbon

: 0.03 Manganese: 2.0 Phosphorous : 0.45 Sulphur :

0.03 max Silicon : 1.0 Chromium : 16 to 18 Nickel

: 12 to 14 Molybdenum : 2.0 to 3.0 Plain 316 SS

nickel range is 10 to 14% and carbon being 0.08%

304 SS has lesser % of Nickel and Chromium and

doesn't have Molybdenum at all. Tube gap and

Thickness / SWG / AWG of tubes Ravi's tubes

sizes used were: Outer Pipe OD : 25.317mm

Thickness : 14 SWG or 2.032mm ;Outer Pipe ID :

25.317mm - (2.032mm x2) = 21.253mm

Inner

Pipe OD : 19.930 mm ;left:334">Thickness : 14

SWG or 2.032 mm Gap is 1.323mm ( 21.253mm -

19.930mm ) This was adjusted to both the sides as

the inside pipe is centered is 1.323/2 = 0.6615 mm

on either sides of the inner tube. So effectively

the gap between the pipes is less than .670 mm.

Ravi went for a lesser gap by increasing the

thickness of the outer tube. Ravi had some

difficulty in the alignment of pipes as they were

shorting. He had to get them straightened on a

pipe alignment machine. Ravi does not suggest that

people without engineering skills go for this

small a gap, but is convinced that the higher

output of my setup could be due to this

smallgap. SWG stands for Standard Wire Guage

Suggestions are, you really don't want an outer

tube smaller than one inch, so that pushes us to

the 2 mm wall thickness. The inner diameter of a

25.4 mm tube 2 mm thick (14 SWG) is 21.4 mm, so

for a 1 mm gap, the inner tube needs to be 19 mm.

The outer diameter of a 3/4 inch tube is 19.05mm,

which would give a gap of 1.175 mm. For a 1.5 mm

gap, you would need an inner tube diameter of 17

mm.

If you

were to use the 1-inch 16 SWG (1.626mm), then it

is difficult to determine the exact wall

thickness, so you should check with the supplier.

In that case, a 20 mm inner tube would give 1.1 mm

(or 1.112 mm) and if the inner tube has a diameter

of 3/4 inch or 19.05 mm, it would give a gap of

1.575 mm (or 1.587 mm). Ravi suggests, Order for

an outer pipe of 1 inch (25.4mm) OD and a

thickness of 16SWG (1.6mm) and an inner tube of

20mm OD. This size should be available

commercially anywhere. With this you can get a gap

of 1.1mm.If youwant lesser gap than that just

increase the thickness to 14SWG (2.0mm), this

should give you a gap of 0.7mm but is very

difficult to align as the spacing is close.

Calculation: (Both setups have same tube

diameters) Dave's WFC: 6 tube of 5 inch length.

Considering the gas generating heights of 6 tubes

x 5 inches = 30 inches in length/height. Ravi's

WFC: 9 tubes of 9 inch length. That's an increased

reactive surface area of over 150% than Dave's.

Dave's and Stan's systems had a spacing of 1/16"

(1.5875mm). Ravi's pipes have a gap of less than

0.670mm (could be the main reason for the higher

efficiency in his unit). Dave

Lawtons Cell What

also must be taken into account is that Ravi is

using 9 tube sets of 9" length and the inner being

1/2" more than the outer for connections. Dave

used 6 tubes of length for his 300%

OU.

Stan's

were 9 tubes of 18 inch length on his

demonstration electrolyzer and in one of the

videos available. In Stan's version there are

claims that he's making 1700% OU over Faradays Law.

When compared to this efficiency Ravi states he

has some more work to do. However any OU is good

OU :). Tube holders You

Tube tutorial Jamie's Replication - Making of the

tube holders

Pre

preparation and conditioning Preparation of

the Tubes: IT IS ADVISED THAT POLISHED TUBES ARE

NOT TO BE USED IN MAKING THE WFC. If one is to use

them make sure they are not Nickel plated or Hard

Chrome plated pipes. If they are Plain SS 304L or

316L but polished you must use a sand paper on

them before hand. The brightness of your tubes

reflection is based on how small a grit of sand

paper you use. The tubes have been fixed to a

lathe and sanded with very fine grit paper to

remove any oxidation on the surface after

annealing of the pipes. The inner tubes need to be

sanded to remove all discoloration (oxides). Use

as small a grit to get fine scratches and when you

condition at low amps the bonding between the

white coat (explanation later) and the metal is

good. Do not try high amp conditioning

at the start as you want a thin fine layer on the

fresh metal. If you order large pipes and

cut them, you need to get the tubes annealed once

they are cut and finished to lengths before

being assembled. It's done in a separate inert

atmosphere furnace of Nitrogen or Argon. You

have people who do heat treatment or metals

they'll give you the procedure if you tell them

the grade you are using. Tell them that you

need a bright anneal in nitrogen or argon

atmosphere. Annealing is done after every cold

work operation and at the finishing stage to reset

the lattice structure. As we are cutting the pipes

and slightly finishing the surfaces with sand

paper to remove any imbedded impurities during

tube drawing, it's all cold working. So you need

to relieve these induced stresses in the lattice

through annealing. Ravi advises - Use an abrasive

cutter or a saw and then anneal them as you

induce a lot of stresses in the lattice during

cutting due to the hot and cold areas. If you use

laser then you could cut the annealed tubes as you

are not inducing any mechanical stresses during

the cutting but you could check along the

length with a compass and see if there's

any difference. Take a compass close to the tubes

and you can usuallysee it deflecting before

annealing but once the annealing is done the

deflection is a [Stanley Allen Meyer Page 15]fraction of

what you have seen before on the same tubes or

none at all, this is what youwant.Assembly

options- It appears that Dave Lawton used

insulated copper wire to connect to his tubes.

Ravi used spot welded stainless steel wire on his

tubes. Originally Ravi had his wires too long

which had a negative impact on his efficiency. He

then had to shorten them. 17342;left:115">Video

-New copper leads being connected by shortening

the length of previous leads

As per

Stan's Patent each inside tube is connected to an

individual variable resistance. He has 18 leads (

9 +ve and 9 -ve). Ravi has since advised that

copper leads covered with high temperature

automotive silicone sealant are better than SS

leads. The RTV silicone is to be applied only at

the exposed copper connecting the pipes and no

where else. Or alternatively, you can construct

the cell as seen from Panacea's endorsed

version.the hydrogen

shop"

17744;left:342">http://www.thehydrogenshop.com/

;left:0">

Pre

preparation and conditioning Preparation of

the Tubes: IT IS ADVISED THAT POLISHED TUBES ARE

NOT TO BE USED IN MAKING THE WFC. If one is to use

them make sure they are not Nickel plated or Hard

Chrome plated pipes. If they are Plain SS 304L or

316L but polished you must use a sand paper on

them before hand. The brightness of your tubes

reflection is based on how small a grit of sand

paper you use. The tubes have been fixed to a

lathe and sanded with very fine grit paper to

remove any oxidation on the surface after

annealing of the pipes. The inner tubes need to be

sanded to remove all discoloration (oxides). Use

as small a grit to get fine scratches and when you

condition at low amps the bonding between the

white coat (explanation later) and the metal is

good. Do not try high amp conditioning

at the start as you want a thin fine layer on the

fresh metal. If you order large pipes and

cut them, you need to get the tubes annealed once

they are cut and finished to lengths before

being assembled. It's done in a separate inert

atmosphere furnace of Nitrogen or Argon. You

have people who do heat treatment or metals

they'll give you the procedure if you tell them

the grade you are using. Tell them that you

need a bright anneal in nitrogen or argon

atmosphere. Annealing is done after every cold

work operation and at the finishing stage to reset

the lattice structure. As we are cutting the pipes

and slightly finishing the surfaces with sand

paper to remove any imbedded impurities during

tube drawing, it's all cold working. So you need

to relieve these induced stresses in the lattice

through annealing. Ravi advises - Use an abrasive

cutter or a saw and then anneal them as you

induce a lot of stresses in the lattice during

cutting due to the hot and cold areas. If you use

laser then you could cut the annealed tubes as you

are not inducing any mechanical stresses during

the cutting but you could check along the

length with a compass and see if there's

any difference. Take a compass close to the tubes

and you can usuallysee it deflecting before

annealing but once the annealing is done the

deflection is a [Stanley Allen Meyer Page 15]fraction of

what you have seen before on the same tubes or

none at all, this is what youwant.Assembly

options- It appears that Dave Lawton used

insulated copper wire to connect to his tubes.

Ravi used spot welded stainless steel wire on his

tubes. Originally Ravi had his wires too long

which had a negative impact on his efficiency. He

then had to shorten them. 17342;left:115">Video

-New copper leads being connected by shortening

the length of previous leads

As per

Stan's Patent each inside tube is connected to an

individual variable resistance. He has 18 leads (

9 +ve and 9 -ve). Ravi has since advised that

copper leads covered with high temperature

automotive silicone sealant are better than SS

leads. The RTV silicone is to be applied only at

the exposed copper connecting the pipes and no

where else. Or alternatively, you can construct

the cell as seen from Panacea's endorsed

version.the hydrogen

shop"

17744;left:342">http://www.thehydrogenshop.com/

;left:0">

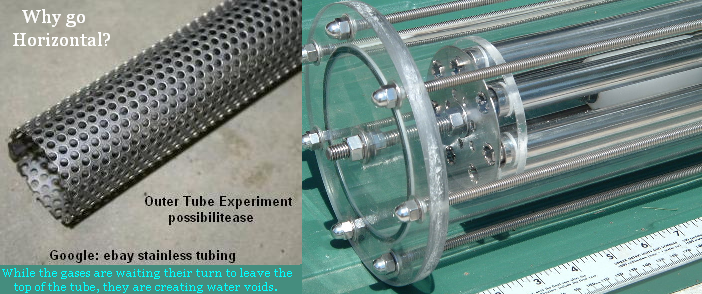

Another

construction option is illustrated in the

following isolated wire plexi glass design. If

using the sealed copper wire option, the ends of

the copper wire needs to be sealed with high

temperature heat resistant silicone sealant and

should not contact water, as this generates a lot

of greenish brown muck. Therefore put silicone

sealant or automotive gasket silicon sealant all

over it so that the water doesn't touch any of

these parts. Then use the sealant over the exposed

copper wire. For stainless steel lead in wire, the

thinner SS wire you use the higher the electric

resistance. If you use SS go for the thickest

possible leads you could weld. It is advised

toreduce the outside length of the wires as much

as possible to reduce resistance. Go for at least

3.0mm or higher to reduce the electrical

resistance. Panacea choose to spot wield stainless

steel wire onto our tubes. Our wires were 4mm

thick. DO NOT USE 316L AS LEAD WIRE THEY HAVE TOO

HIGH A SPECIFIC RESISTANCE TO BE USED AS LEADS

approximately 46.8 times that of copper. Incase

you want to introduce a resistance on the negative

lead (60a….to 60n in Stan's Patents) you could

always used a wire wound variable resistance. This

seems to have been the problem of leads heating

up. ;left:377">Specific Resistances:

;left:345">Copper : 1.63 MICROHM-cm 316 : 75

MICROHM-cmRavi chooses to use plastic tubing

around his wires only to avoid shorting of the

positive & negative leads. Ravi's cell showing

the plastic insulated SS wire. The SS wires act as

resistors. The specific resistance of 316L is

around 75 Micro-Ohm-cm and that of copper is 1.72

Micro-Ohm-cm. The leads heat up when higher amps

are drawn by the freq gen. I've replaced the leads

up to the bottom of the WFC with 4 Sq.mm double

insulated copper wire and the heat generation did

come down. When choosing clamps for your water

fuel cell. Always choose Stainless steel

Clamps,never choose galvanized clamps, If the

clamps rust then the nickel % is extremely less

for it to be used. Galvanized are basically Mild

Steel screws / clamps which are zinc plated. The

plating would come off in no time and you will

have brown muck all over. They have to be SS or

the brown muck would never stop. Extra clamps for

support are ok but have to be SS. 300 series

(302,304,306, 308, 310, 316) only and not 200 or

400 series. For spacing between the tubes any

nonconductive flexible material will do even the

speaker wire plastic covering will work with

this. 20194;left:211">Video

1: This video shows the innards of the WFC without

water ;left:0">

20479;left:118">Video

2: This video shows freshly filled Tap

Water. No

other impurities (Read no Salts or

Acids

or anything at all just plain tap water and not

distilled water) added. Additional

optionsIn one of Stans patents he talked about

using polyoxymethylene

(Derlin) which has a high

dielectric constant. He used Derlin on the outside

of the outer pipe and the inside of the inner pipe

to contain the electron leakage. The barrier

formed by the conditioning (explanation below)

coating has a comparatively lesser dielectric

constant than the Derlin material thickness used.

Also D14 originally talked about creating slots in

the outer pipes. This has not been confirmed yet,

and should be investigated further.

408">Conditioning Average time takes 4

weeks, based on Dave's and Ravi's reports. The

impurities in the water differ from place to

place. This makes a huge difference. You could see

this difference by using ground water and water

from streams and lakes which has been exposed to

sunlight. Ravi chooses to use tap water. Electrode

conditioning helps by providing an appropriate

insulating layer on the electrodes and that helps

to lower useless current leakage through the

water. Check

this

video.

You can see the confirmation of non conductivity

of the layer formed. The

white

insulating coating formed during conditioning is

non conductive in between the tubes (pipe gap) so

you need to take it for granted that the process

is basically dielectric breakdown of the bonds.

The initial conditioning is very important. Ravi

recommends to only using the following process

described. DO NOT GO ABOUT CONDITIONING WITH

HIGH AMPS ONLY AS YOU'LL ENDUP HAVING A

WEAKLY BONDED COAT ON YOUR NEGATIVE TUBES. LOW

AMP CONDITIONING IN EXTREMELY IMPORTANT FOR

PROPER BONDING OF LAYERS TO THE BASE METAL and

the previous layers. The bond strength

of the layer can be increased further as after

every cycle of conditioning. You need to stop for

an hour at least. During this period you can

let the pipes air dry after every full

cycle. This compacts the layer even more due

to the loss of moisture from the surface. Then

change the water and go about the next

conditioning cycle. Never touch the layer till it

dries up completely. Ravi's procedure

originally given to him by Dave Lawton:

1. Do not use any resistance on the negative

side when conditioning the pipes. 2.

Start at 0.5 Amps on freq gen and switch off after

25 minutes and stop for 30 minutes

3.

Go to 1.0 Amps for 20 min and stop for 30

min 4. Go to 1.5 Amps for 15 min and

stop for 20 min 5. Go to 2.0 Amps for

10 min and stop for 20 min 6. Go to

2.5 Amps for 5 min and stop for 15 min

7. Go to 3.0 Amps for 120 to 150 seconds.

You will then need to check if WFC is

getting hot, if it does you need to

reduce the time. AFTER THE 7 STEPS ABOVE

LET THE WFC STAND FOR AT LEAST AN HOUR BEFORE YOU

START ALL OVER AGAIN. You would hardly see any gas

generation at the beginning and it makes a lot of

brown muck. It took Ravi and Dave about one month

before the brown muck disappeared.

Brown

muck produced Change

the water after every cycle initially. DONOT

touch the tubes with bare hands if the tube

ends need to be cleaned of muck use a brush but do

not touch!! Ravi's experience showed that

leaving the brown muck in water for the next cycle

goes on to heat up the water and you need to avoid

this. Over a period of time you will see a

reduction in generation of the brown stuff. When

the muck is reduced you should see a gradual

decrease in the Amp draw for the same amount of

generation. An artist painting brush would be

perfect to clean the tube ends during and after

conditioning. When you are conditioning you don't

need to connect the VIC -voltage intensifier

circuit (Toroid + Inductors). Eventually the pipes

will not produce any brown stuff at all. At this

point you should now have a very good generation

of gas. You will get a whitish powdery coat on the

surfaces. Never touch the pipes with bare hands

once this comes on.

A

white insulation coating formed on the negative

DO THE

CONDITIONING IN A WELL VENTILATED AREA OR

PREFERRABLY CLOSE THE TOP AND VENT THE GAS OUT IN

THE OPEN. AS THE WFC IS LEFT ON FOR QUITE SOMETIME

EVEN SMALL AMOUNT OF GENERATION CAN GET

ACCUMULATED IN A CONSTRICTED SPACE AND COULD BE A

HAZARD. The above process is to be done after

annealing the pipes. See to it that no oxide

formation is left on the pipe and use a detergent

to wash off the pipes and rinse them thoroughly

with fresh water. Then assemble the setup

including the leads and base. Finally flush the

pipes with lots of fresh water do not touch the

pipes with bare hands after this.

Aaron's

video explaining about the non conductive

Layer When

the power is switched on you see bubble formation

on the external surfaces of the outer tubes just

like in the video. This happens all along during

the conditioning process. Ravi states he remembers

Dave saying that you know the tubes are

conditioned when these bubbles stop forming on the

external tube surfaces and you see a white powdery

coat on the tubes. Ravi went on conditioning even

after that and ended up with larger bubbles. 0Ravi

states it is critical that people follow the

conditioning procedure as you get very uneven coat

formation on the surface if you use High Amps for

long periods. When you go above 3 Amps there's a

possibility of the coating flaking off. The

bonding between layers would not be that strong.

These layers form one over the other after every

cycle of conditioning. The small time high Amp

conditioning gives you an uneven coat and the long

time low Amp conditioning evens out this more or

less. The longer you use Low Amp conditioning the

better the end outputs! Ravi has also used 0.2

amps for low amp conditioning. This is ideal how

ever time consuming. If you do the procedure

described above and still wish too build up a

better coat afterwards then you can use the 0.2

amp conditioning process afterwards.

A lot

of people have been asking what the conditioning

coat of Ravi looks like plus why they shouldn't

touch and why it can't be dismantled and

reassembled. Check: http://www.youtube.com/watch?v=leAtiaCygng

WFC

Circuits Alternator

Stevie's

Unit For

some there may be more losses in the alternator

than the solid state version. The original

alternator schematic will be included. It is

recommended you use the solid state version and

get it working first. The alternator was only done

by Dave to mimic the car's operation in Stan's

technology.

Bifilar

Inductors Test

One

needs to experiment and search for superior

circuitry as Stan Meyer did. Stan had a better

circuit which he never disclosed - the UK TV

documentary states that Stan would not even let

them point a camera at his more advanced cell. The

inductors were actually part of the VIC. Dave had

used the exact specs (100 turns, wire dia, etc) of

the inductors mentioned in Stan's US Pat 4936961.

Then Ravi had later added the toroid and the diode

as per the VIC which increased the efficiency

compared to using only the inductors. Ravi had not

used the variable inductor mentioned in the

patent. His were wire wound like the ones

mentioned in the old D14, pg7.

Ravi

states "The inductor on both positive and negative

is a must. I've made it on a Ferrite rod

of 25 mm length 100 turns of Double Enameled

Electrolytic Copper (99.99%) of 22 SWG

(0.711mm dia)" which was what Dave suggested."

You will notice an increase in gas generation when

the bifilars are connected. Try with one in the

beginning if it heats up increase the number of

inductors.

Ravi

used 9 individual bifilar wound inductors for 9

tubes with 22SWG magnet wires. The inductors and

the toroid (Part of the VIC) do heat up after a

while and the efficiency comes down this happens

due to the temperature coefficient of resistance

of copper. So the answer to this problem would be

to use bigger inductors and toroids and thicker

wires. Voltage intensifier

circuit

The

VIC specs give as per patent 4936961 in Stanley Allen Meyer Page 6 of

the toroid size would probably be OK for a very

small setup but may be not for the lengths and the

numbers Ravi is using. Stan gave a basic idea of

how it should be but we need to figure out the

specs for our own build sizes. My WFC is not a

done thing its still in an evolutionary stage and

lot of combinations with the inductors are yet to

be tried out. The VIC basically needs a toroidal

core and a 600V 40A metal diode with a heat sink.

The specs of wire sizes and turns are in Stans US

pat 4936961. He has a variable inductor in the

patent on the -ve side but what Ravi has is a

regular inductor, two of them one on positive and

one on negative. Ravi states he would not suggest

using bifilars as inductors as they ended up

shorting three of the tubes. The 100 ohm 0.25W

resistors were replaced with 100 ohm 0.5W as 0.25W

kept burning out. The bifilar inductors are wound

on ferrite cores using the recommended turns

stated in the original D14 document. When using

Ravi's version, you must use the diode to cut out

the back EMF, Ravi states that this is very

important! And is what gives you huge

generation, this part is not mentioned by Dave or

in D14. You end up getting all the juice from the

system only if your tubes are conditioned

enough. 30697This

video shows the

higher output is all to do with the inductors

mentioned in the D14 circuit

and conditioning and slightly through the

resistance wire to reduce the current draw. Even

without the resistance you can get the same output

but another 0.3 to 0.6 amps extra but I feel this

could be offset by making a bigger inductor. Just

go on conditioning and keep reducing the amp draw

to the WFC gradually and the generation would kind

of remain the same even at very low Amps. Once you

condition the tubes your generation will

dramatically increase and the current required

will fall by leaps. It took Ravi almost 3 months

approximately to reach these

outputs.

Above

is a picture of the multiple bifilars Ravi tried

on the WFC. These were connected to each pipe

individually. Diode used 1200 V 40 Amps. Solid

core length 8" wound with .711mm conductor end to

end. The generation increased by approximately

another 10cc of gas for a 20 second period

compared to regular wound inductors. This works on

efficiency!! Need to try out other combos to

see if it can increase some more.

Variable

resistors Ravi also experimented with using

Nichrome 80/20 Resistance Alloy wire in 1.6 mm

diameter as the variable resistor. This has

resistance of 0.52 Ohms/mt. The efficiency of the

cell comes down initially. Ravi states that "if I

dont use it for about three to four days but about

ten to fifteen minutes after its switched on it

gets back to the higher efficiencies". If you

go through Stan's patent 4,798,661 on page 2 Figure

1, these variable resistors are designated by the

numbers 60a to 60n which are individually

connected to each of the inner tubes. Ravi has not

tried the immersed exciter array in figure 1 this

could probably increase the efficiency even more!

Connecting the unit to an ICE The main

reason why Ravi wanted to free source this process

was to be used for vehicles as this unit cannot /

would not be allowed to be sold commercially as it

can give you at least 50% gain in mileage! This

would reduce the world's automobile pollution

problem drastically. Power generation through an

ICE is not that feasible due

to the

high wear pertaining to automobile engines when

used continuously for months together. As per

Ravi's calculations the engine needs a re-bore

every two months if used continuously!!. So the

only viable alternative is to use in small

Turbines. For backup gensets, IC Engines could be

OK. When connecting to an ICE there are a lot of

minor to major modifications and tune ups need to

be done depending on the engine type and year of

make. Video

3: This video is after the top is sealed and with

an input of 0.5 Amps from

the Frequency Generator.

33763;left:373">Frequency

Generator All Photo's Supplied by http://www.vptechno.com/

Front

view

Rear

view

Panacea's

first test cell Variable

inductor Ravi is trying some variable inductor

Concepts.

Faculty

information Solid

state version Ravi advises that if the FETS in

your signal generator are blowing, the best option

would be to alienate the freq gen by introducing

the VIC in between. Go through Stan's USPat

4936961 for the construction details of the VIC.

All that is required are the inductors and a

torroid to be wound as per the patent. Ravi states

to use larger diameter wires and a larger torroid

to avoid heating up of the windings. Also use a

high speed 600-1200V 40 Amp diode in between the

positive of the inductor and the toroid's secondary.

Problem solved!

[Stanley Allen Meyer Page 34] Originally

Dave's 100 turn inductors were actually made from

this VIC description. He did only the inductors

and left out the torroidal and the diode. The

torroid is the one that isolates the frequency

generator and steps up the voltage. Ravi reports

that he has already tested it and it improved the

gas generation even more. Faraday

calculationsCalculating 2.4 Watts x 1 hour

long applied / liter. 2.4 Watt hours of energy per

Liter. That's multiplied with the hour not divided

by the hour. Volts x Amps = Watts 12 x 0.51 = 6.12

watts The generation is around 7 cc/sec of H2 + O2

This converts to 4.66 CC of H2/sec which converts

to 16.776 Lits / hour 16.776 x 2.4 watts

(Faraday/lit/hour generation) = 40.262 Watts. Ravi

seems to be generating the equivalent of 40.2

watts as per Faraday with just 6.12 Watts. This

would mean he is generating 550% excess as the

above works out to 40.2/6.12 x 100 = 656.86%

656.86 - 100 (Faraday) = 556.86% Over Unity !!

Presently the approximate volumetric gas discharge by an

inverted measuring flask is given below:

INPUT--H2+O2 cc/sec---H2 only cc/sec---H2 Liter/hr

0.5

A-----7.00--------------4.66-------------16.776

1.0

A-----8.66--------------5.78-------------20.808

1.5

A-----11.66-------------7.78-------------28.008

2.0

A-----14.00-------------9.33-------------33.588

3.0

A-----16.36------------10.91-------------39.276

4.0

A-----18.00------------12.00-------------43.200

H2+O2 was calculated on an average basis for

collection time of 30 secs. I'm not very sure of H2

and O2 volumes as I've calculated H2 as 2/3rd the

volume of the total and O2 as 1/3rd the volume.

Incase im wrong please do let me know how to

calculate these. Video

of Gas flow test The

gas collected was over 150CC could be 160 / 165CC.

As some might say that there could be Steam /

Vapour / Mist lets just take the output as 150CC

in 20 Secs. This comes to 7.5CC of gas/Sec at

0.48A - 0.50A. Last I checked with the old leads

was 7.0CC gas without any thing removed from the

generation.

This

video shows

the voltage input and the amps in both digital and

analogue meters. One

part of the pulse circuit was switched off (left

side 555 in the D14 with the switch on pin 3) and

you can see that the current draw is over four

fold. Conditioning The conditioning time

was pretty long. The surface forms a layer of

Nickel oxides along with Chromium oxide as well

and in the case of 316L you have @ 2% Molybdenum

in the SS alloy but you could be right about the

Cr oxides acting as a dielectric. Nickel

passivates in air and forms oxides like Zinc in

galvanised form. Example: incase you need to

electroplate on nickel you need to reactivate the

surface layer before the plating process or the

plated layer just peels off. The initial

conditioning is very very important and I

recommend to use the process I posted as with

lesser Amps you form a thin fine grain layer and

once you increase the Amps the grain size of the

deposition layer increases. The bigger grains can

come off the surface easily...so once you do this

you go back to the longer time low Amp

conditioning in the process I posted...this again

reinforces the larger grains deposited during the

high Amp conditioning to bond to the base /

previous layer. have never posted this info before

but this is the reason why different Amp levels

are used in the process. I have to give the reasoning

for the low Amp conditioning as a lotof replications seem to be

taking the short cut method of conditioning at high Amps

to save time. PLEASE DO NOT GO ABOUT CONDITIONING WITH HIGH AMPS

ONLY AS YOU'LL END UP HAVING A WEAKLY BONDED COAT.

LOW AMP CONDITIONING IS EXTREMELY IMPORTANT FOR PROPER BONDING OF LAYERS TO THE BASE METAL

And the previous layers. FOLLOW THE POSTED PROCEDURE.

It�s a time consuming process but worth the effort.

The bond strength of the layer can be increased further

as after every cycle of conditioning you need to stop for at least an hour.

During this period you can let the pipes air dry only after every cycle

...this compacts the layer even more due to the loss of moisture from the surface...

then change water and go about the conditioning cycle.

Never touch the layer till it dries up completely.

http://www.mtaonline.net/hheffner/GlowExper.pdf

http://www.mtaonline.net/~hheffner/GlowExper.pdf

Ravzz

states- IT DESCRIBES WHAT REACTIONS HAPPEN DUE TO

CONDITIONING!! IT SAYS THIS CONDITIONING COAT FORMS

IN WATER WITH NICKEL.....WELL SS316L HAS THE MOST

AMOUNT OF NICKEL IN THE 300 SERIES! This even

confirms the reason why there is a glow in the WFC

and even confirms that it can be seen only when

its dark...and that's what I had seen. It now looks like

this is the key to what happens during and due to

conditioning.

[Stanley Meyer Page 36]

The doc even talks aboout cold fusion taking place in the cell

.....and over unity due to the conditioned coat!!

These docs should put an end to the reason why conditioning

is so important and why the step conditioning

needs to be followed. http://www.mtaonline.net/~hheffner/BlueAEH.pdf

http://www.mtaonline.net/~hheffner/GlowExper.pdf

http://www.mtaonline.net/~hheffner/OrangeGlow.pdf

http://www.mtaonline.net/~hheffner/Key2Free.pdf

The

following may be related, could the plasma version

of the "diode effect" mentioned in papers

previously mentionedabove. http://uk.youtube.com/watch?v=rUHeBPBzca0

Additional

options Using

Delrin

This

video shows

the voltage input and the amps in both digital and

analogue meters. One

part of the pulse circuit was switched off (left

side 555 in the D14 with the switch on pin 3) and

you can see that the current draw is over four

fold. Conditioning The conditioning time

was pretty long. The surface forms a layer of

Nickel oxides along with Chromium oxide as well

and in the case of 316L you have @ 2% Molybdenum

in the SS alloy but you could be right about the

Cr oxides acting as a dielectric. Nickel

passivates in air and forms oxides like Zinc in

galvanised form. Example: incase you need to

electroplate on nickel you need to reactivate the

surface layer before the plating process or the

plated layer just peels off. The initial

conditioning is very very important and I

recommend to use the process I posted as with

lesser Amps you form a thin fine grain layer and

once you increase the Amps the grain size of the

deposition layer increases. The bigger grains can

come off the surface easily...so once you do this

you go back to the longer time low Amp

conditioning in the process I posted...this again

reinforces the larger grains deposited during the

high Amp conditioning to bond to the base /

previous layer. have never posted this info before

but this is the reason why different Amp levels

are used in the process. I have to give the reasoning

for the low Amp conditioning as a lotof replications seem to be

taking the short cut method of conditioning at high Amps

to save time. PLEASE DO NOT GO ABOUT CONDITIONING WITH HIGH AMPS

ONLY AS YOU'LL END UP HAVING A WEAKLY BONDED COAT.

LOW AMP CONDITIONING IS EXTREMELY IMPORTANT FOR PROPER BONDING OF LAYERS TO THE BASE METAL

And the previous layers. FOLLOW THE POSTED PROCEDURE.

It�s a time consuming process but worth the effort.

The bond strength of the layer can be increased further

as after every cycle of conditioning you need to stop for at least an hour.

During this period you can let the pipes air dry only after every cycle

...this compacts the layer even more due to the loss of moisture from the surface...

then change water and go about the conditioning cycle.

Never touch the layer till it dries up completely.

http://www.mtaonline.net/hheffner/GlowExper.pdf

http://www.mtaonline.net/~hheffner/GlowExper.pdf

Ravzz

states- IT DESCRIBES WHAT REACTIONS HAPPEN DUE TO

CONDITIONING!! IT SAYS THIS CONDITIONING COAT FORMS

IN WATER WITH NICKEL.....WELL SS316L HAS THE MOST

AMOUNT OF NICKEL IN THE 300 SERIES! This even

confirms the reason why there is a glow in the WFC

and even confirms that it can be seen only when

its dark...and that's what I had seen. It now looks like

this is the key to what happens during and due to

conditioning.

[Stanley Meyer Page 36]

The doc even talks aboout cold fusion taking place in the cell

.....and over unity due to the conditioned coat!!

These docs should put an end to the reason why conditioning

is so important and why the step conditioning

needs to be followed. http://www.mtaonline.net/~hheffner/BlueAEH.pdf

http://www.mtaonline.net/~hheffner/GlowExper.pdf

http://www.mtaonline.net/~hheffner/OrangeGlow.pdf

http://www.mtaonline.net/~hheffner/Key2Free.pdf

The

following may be related, could the plasma version

of the "diode effect" mentioned in papers

previously mentionedabove. http://uk.youtube.com/watch?v=rUHeBPBzca0

Additional

options Using

Delrin

Stanley Allen Meyer Page 37In one

of Stan's patents he talked about using polyoxymethylene

(Delrin) which has a high

dielectric constant. He used Delrin on the outside

of the outer pipe and the inside of the inner pipe

to contain the electron leakage. The barrier

formed by the conditioning coating has a

comparatively lesser dielectric constant than the

Derlin material thickness used. Slots cut into

the outer pipesThe picture below clearly shows

there are slots in Stanley Meyers tubes, light can

be seen though the slots eliminating the

possibility of it being spacers. A Rectangular

slot cut in the top of each tube can clearly be

seen.

Stan's cell in operation. The scene is taken from a

documentary on Meyers Since

we are dealing with an acoustic resonance it makes

sense to create slots in the positive of the tubes

to help mimic the resonant frequency of the

negative tubes. It is not known for sure why Stan

did this at this time. Please consult the original

D14 document for more background info.

WFC by

spike The

original D14 document described a way to create

the same resonant pitch when constructing. Please

consult the original D14 document. An engineer has

contacted Panacea and offers the following advice.

Message: I have duplicated Stan Meyer's work, and

have taken it several steps forward. First, during

assembly of the generator, I have found that you

must tune the tubes to the same pitch. I do it

with a simple guitar tuner. Just clip it to the

tube and strike it with a small brass (to prevent

polarization) hammer. The easiest way to change

the pitch, it's always the outside tube, grind a

notch in it like Stan did. Second, oscillate it

with high voltage, low amperage voltage. Water

resonates at 926khz, and will disassociate at that

range. Before conditioning the generator, briefly

dry modulate it in 5 second bursts, with about 2

min between bursts for about 10 min. You should be

able to hear it hum,and with a practice ear, tell

if one set is out of pitch. I also added a toroid

coil, to produce parahydrogen. Tube size is

determined by the diameter of the cell, be it 4,

5, or 6 but the optimum gap between tubes should

remain .045 to .060. Try to maintain the low side.

You are correct, in that it takes at LEAST 2 to 3

months to condition your tubes. I don't add the

toroid until final assembly, and try to maintain a

1/8' gap from the top of the tubes to the toroid.

I am currently running 70psi in the generator.

-End Cold Current Circuit If you are

experimenting with the cold current circuit, and

wish to alter the values of the circuit components

for example the capacitors.Please keep the

following in mind. Ignoring some relatively minor

construction features, capacitors are all the

same. They act as a reservoir for electrons. If

you have a lot of electrons like in a power

supply, then you need big capacitors - the bigger

the better. If you are passing low frequency AC

through a capacitor, then when the signal is high,

electrons will flow into the capacitor. When the

signal goes low, those same electrons will flow

back out. You need to make [Stanley Allen Meyer Page 39] sure that the

storage capacity inside the capacitor is big

enough to handle the current flowing in and out.

If the frequency is high, then the signal is only

high for a very short time and so not much storage

capacity is needed. Consequently, high frequency

capacitors can be very small in size. BUT if the

capacitor is high quality and has low leakage as a

component, then a large capacitor can do the job

at high frequency just as well (though it is

physically bigger, heavier and more expensive) -

just common sense really. When used in a timing or

oscillator circuit, small capacitors fill up

faster and as the circuit switches over when the

capacitor is full, the generated frequency is

higher. The rate of current flow into a capacitor

is controlled by the size of the resistor feeding

it - the higher the resistor value, the lower the

current flowing through it, the slower the

capacitor charges up, the lower the frequency of

the oscillator. You will see this in, say, Dave

Lawton's circuit where the frequency range is

selected by switching a larger capacitor into the

circuit to get a lower frequency. 47, 10 and 1

microfarad for slow, medium and fast gating while

the high frequency oscillator which is being gated

has 0.22, 0.1 and 0.01 microfarad capacitors

giving a very much higher frequency. (The old

version was drawn with the switches operating in

opposite directions).There is lots of scope for

variations, but typically, 10 microfarad

capacitors are for switching in the 10 Hz or lower

region, 0.1 to 1 microfarad for high audio

frequencies, and 0.01 or smaller for ultrasonic or

radio frequencies. A third party has confirmed

that after speaking to Dave Lawton on the phone

he expressed the opinion that the size

of the capacitors was not particularly important

as the frequency was high. Dave was

doubtful about that and said that the bulb lit

better the larger the capacitor was. So, although

some may see no logic for it at all, it is better

to go with very large capacitors. Note –on the

circuit it looks as it is a DCcap. There is no

such thing as "an AC capacitor" or "a DC

capacitor" there are just "capacitors". They are

all the same, with the slight exception of

manufacturing differences in the materials used.

Tantalum has minimal leakage and can hold their

charge for days on end, but they don't go above 1

mF in capacity. Electrolytic capacitors can have

massive capacities but their leakage can be

massive with the charge bleeding off rapidly from

really big ones. So there is no AC or DC

capacitors, just "capacitors" and any of them can

be used for any application. Low capacitances

can't handle low frequencies properly as they fill

up long before the waveform has returned to zero,

so the waveform gets chopped off and highly

distorted. By showing the capacitors that Dave

used, without making it clear that he used those

capacitors as they happened to be sitting on his

bench at the time he was experimenting with the

circuit. It is highly likely that any electrolytic

capacitor will work in that position. Just whack

one in and see if it works well. A

'common-or-garden' 1000 mF [Stanley Allen Meyer Page 40] would

probably do very well - just try whatever is to

hand. It is definitely NOT the case that Dave

tested lots of capacitors and found that the only

ones that worked were the ones shown in the

circuit.Analogy of the cold current circuit by

Tao Meyer's EEC circuit layouts compared to

Lawton's recently posted EEC circuit that he is

using to power that light bulb, among other loads.

In the first image, Meyer's simple EEC is shown.

In this setup, the 'amp consuming device' is

analogous to Lawton's light bulb. When the water

in the WFC is being split, electrons are dislodged

from the water and as successive positive pulses

happen the electrons are effectively 'sucked up'

by the amp consuming device. So, there are

electrons in the water free, and when a positive

pulse comes, the electrons move to the right

electrode and move through the 'amp consuming

device'.In the second image, Meyer upgraded his

setup and included a triggering mechanism whereby

he can choose when he applies the positive pulses

to the 'amp consuming device'. So Meyer could send

some pulses to the WFC plates and split up the

water,

[Stanley Allen Meyer Page 41]

then he could trigger the switch and

send pulses to the 'amp consuming device'whereby

the electrons from the water would flow through

it. Lawton on the other hand, has modified

Meyer's EEC a bit with the addition of those

extra high capacity caps. These caps would, by

thinking about it, charge up via the continued

HV pulses that are being applied to the WFC,

analogous to a Bedini type setup. The electrons

would then move to and from the caps and cause

fluctuating current to hit the bridge rectifier

and power his load. All in all, it seems there

can be many different ways to implement the

EEC.Insertion of a laser into the resonance

cavity in Stanley Myers' research papers, is the

insertion of a laser into the cavity, injecting

certain light frequencies into the cavity to

assist in the fracturing process. This would be

done by using a cell with cavity placements for

high frequency light-emitting diodes in the area

of 395 nm wave length. This cell would be

conditioned, prepared and coils wound to suit.

After the conditioning process the cell would be

finally tested with light-emitting diodes.

Annealing by Rick To understand this, you

must first understand the manufacturing process.

You are talking about "drawn" pipes, or tubing,

which refers to the manufacturing process of

seamless pipe or tubing. To simplify, let's

assume that it is actually pipe. During the

manufacturing process, the metal for the pipe is

first formed into a solid billet (a solid metal

casting) of cylindrical shape. The billet is

then "drawn" (pulled) over a piercing rod, which

results in the hollow core of the pipe. You can

just imagine the stress that occurs to the metal

during this forming process. If left in this

state, the stress points can become hairline

fractures that will spread and grow larger,

especially if the pipe is heated and/or cooled

during use, or subjected to high pressures, and

of course that would eventually lead to failure.

Seamless pipe is normally chosen by fabricators

because of its superior strength as compared to

seamed pipe, and therefore most seamless pipe

does pass through an annealing process.

Annealing is a process whereby the formed pipe

is heat treated by placing it in a special oven,

at a closely regulated temperature, for an

extended duration of time. This heating relaxes

the metal to relieve the stress points. After

annealing, some impurities will have risen to

the surface, and the metal will appear somewhat

discolored. High quality stainless, or other

smooth surface metal piping, would have its

surface ground and then polished with special

equipment. So unless you manufactured the pipes

yourself, there's a good chance that they may

already have been annealed. Check with the

manufacturer if you are not certain. The author

of the article which you quoted probably

purchased annealed, but unfinished pipe, and

therefore was sanding the pipe on a lathe, with

fine emery paper, to obtain a surface

[Stanley Allen Meyer Page 42]similar to manufacturer polishing.

Incidentally, FYI, pipe sizes refer to the

inside diameter of the pipe, while tubing sizes

refer to the outside diameter. You probably

already know that, but I thought I would point

that out because the terminology is often

confused or misused. It is interesting to me to

note that some people believe that Stan Meyer

actually may have tuned his pipes by slotting

them at the top, as is done in tuning some types

of organ pipes. While pipes in water would not

generate the same tones or harmonics that they

do in air, the technique could be useful in

manipulating resonance, and the degree of

harmonic distortion produced, and this could

have a considerable effect on the end results of

Hydrogen production. I see that you are still

just slightly confused and may need some further

clarification. Ravi is right in saying that

metal cutting can induce new stress points, and

that is particularly true when the cutting

method produces a significant amount of rapid

heat buildup, such as when using a cutoff disc.

Stainless pipes are difficult to cut, and thus

are very susceptible to heat buildup unless you

go very slow and use an abundance of coolant. I

would suggest that anyone building a tube or

pipe project order their material laser precut

to the desired length. That will save work,

time, and expense. If you purchase precut and

polished ss pipes, you only need to sand the

inner surfaces of the larger pipes, and the

outer surfaces of the smaller pipes that go

inside the larger ones. These are the active